WHY DENIM REPAIR

The Art to Denim Darning

Over the past 50+ years, denim repair and denim darning has been slowly disappearing from cities across the world. This is mainly because the machine technicians have either retired or passed and the industrial sewing machines that used to do this type of work have been sold, transported to other countries, or they have been scrapped and sent to a landfill. There is currently a revival occurring across our nation for denim repair and many people are starting to realize that the art of denim repair is in fact just that, it’s an art. Trying to find a good denim repair specialist is harder than it should be.

There was a time where, manual labor was part of life, and the stretchy jean was not yet invented yet. 100% cotton non-stretch denim is and was expensive and repairing your jeans was a cost effective way to continue to enjoy your investment. 100% cotton jeans also do not stretch and finding a perfect pair is hard. Comfort has replaced function. What may have taken trying on 10-20 pairs of jeans and understanding the silhouette of the human form, has been re-written by the creation of how much spandex is in the denim. Big business has also realized that it is cheaper to make a lighter ounce denim, it doesn’t last as long, and therefore, you have to buy a new pair more often. The cost of making a pair of jeans, is by far, much more expensive than most people understand. Automation, green washing, and the practice of modern day slave labor has made it difficult to know who to trust and what to believe. If you live in the United States, there is a fair chance you don’t own a piece of clothing that was made here and the quality of the jean is not what it was 20+ years ago.

The United States used to be one of the top producing countries in the world for clothing production. Now, less than 2% is clothing sold in the United States is actually made here. The United states is one of the top consuming countries in the world. This just does not make sense to me. People used to knew someone or had someone in the family that knew how to fix clothing. Unfortunately, many of these family traditions are not being passed down and the art of mending, fixing, and darning has been replaced with the practice of fast fashion. People have been brainwashed by fast fashion companies and big business to think it is just easier to buy a new pair.

I have personally been fortunate enough to learn about the process of making a pair of jeans... starting from seed. I have visited and talked with farmers in the Carolinas and visited a denim manufacturing plant. You may ask why is this important? I believe, in-order to understand why you should be repairing your jeans it is important to question the WHY. There are some that just see denim repair as a trend and it makes you look cool. There is definitely something cool about being a select few that own the equipment to do it, but, the cooler part is keeping things out of the landfill. I have done pretty extensive research in the denim repair community and there are definitely people and companies out there that keep profit as their #1 driving strategy. I made a choice a few years ago that being a famous denim repair specialist was not my #1 priority. Providing a service to my community and keeping denim out of the landfill is much more important.

In the denim repair world there are two worlds: keeping the repair hidden as much as possible and the function of the repair. The equipment is as important as the repair. Without the proper equipment the repair will probably be more visible and it will not last as long. The Singer 47w70 is considered the holy grail of denim darning machines. Here at TKCC, we have a first generation and two second generations of these machines. These machines, when tuned correctly, have the ability to create seamless denim repair. These machines can actually create a type of lockstitch that is used to repair holes without the use of fabric behind the stitch. Watching a knowledgeable denim repair specialist work their magic is quite a spectacle.

I have also learned that many repair specialists use the Singer 47w70 as a marketing tactic and use table machines to complete their repairs. 90% of the repairs in our shop are done as they were when these machines were first created… functional denim repair. The cost will almost always be under what the cost is of a new pair of jeans and many of the denim repairs can be done within 24-48 hours. There are many repair specialists charging $100+ for repairs and 4-8+ weeks to repair them. In my opinion, this defeats the purpose of why these machines were created.

Small holes are usually completed as you wait and can be done in 5-10 minutes and repairs start under $10. The main goal at TKCC Denim Repair is to try and keep denim out of the landfill and to save your perfectly worn-in jeans from the landfill. I also repair stretchy jeans, it is not my favorite, but in-order to continue to help my customers, I made the choice to offer this service. Many repair specialists do not work on stretchy jeans.

If you are interested in getting your denim repaired, please follow the rules, fill out the form, and send in your denim. Most mail-in repairs can be done within 5-7 business days and will be sent back promptly. All denim must be fully laundered in-order for me to complete the repair. I charge a $30 shipping and handling charge to return your jeans if you do decide not follow the rules.

COST: Generally for functional denim repair to get you back enjoying your pair of jeans again, for every square of darning the cost is roughly $10/per square inch. this includes the denim backing and/or stabilizer.

HOW TO SEND US REPAIRS: Fill out the repair .pdf form and send us your denim. Our mailing address is:

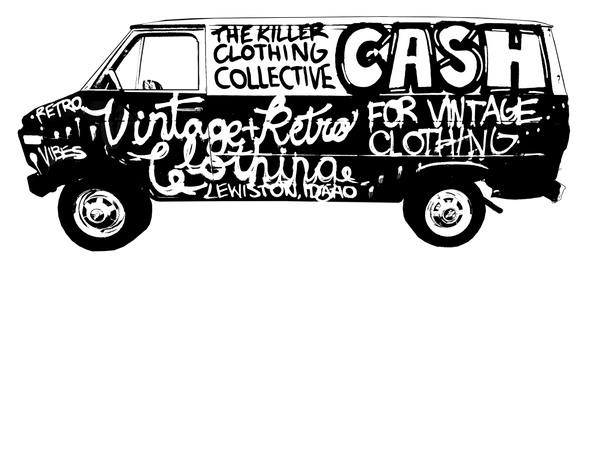

DOWNLOAD DENIM REPAIR FORM HEREThe Killer Clothing Collective

Attn: Denim Repair

519 Thain Road, Suite A

Lewiston, Idaho 83501

If you have any questions feel free to send an email to info@thekillerclothingcollective.com or for a quote. Pictures must be included to create an estimated repair cost.